Product Feature

Advantages

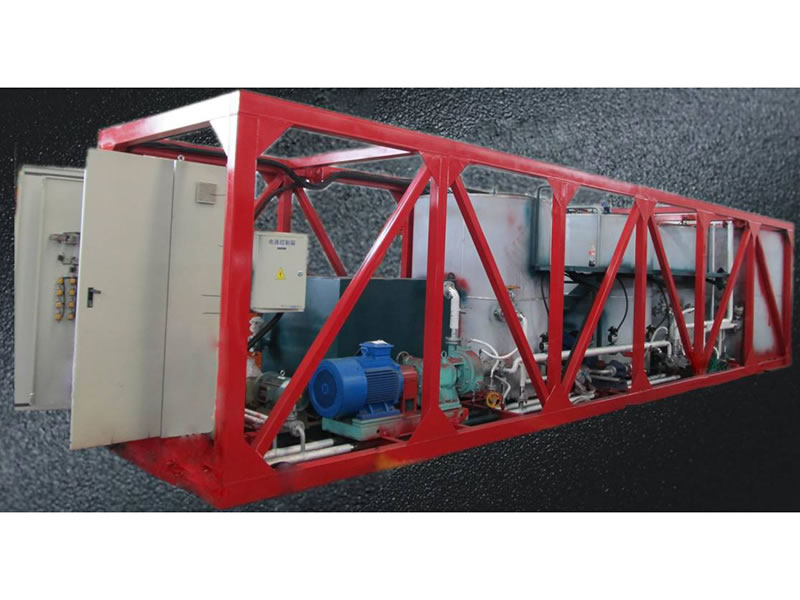

1. We mainly offer MTR10A Modified Emulsified Asphalt Equipment for midrange servers. This equipment quality is guaranteed. It features energy conservation, easy installation and easy use.

2. It adopts high-power colloid mill, which makes it possible to produce modified emulsified asphalt and common emulsified asphalt at the same time.

3. This equipment solves the ratio problem between asphalt and liquid soap.

4. The structure of Emulsified thinning tank could effectively reduce the time for collocating emulgator.

5. Collocating tank, storage tank and matrix asphalt tank all adopt the aluminum silicate material as insulation layer and have favorable heat preservation performance. They could be heated by the built-in heat-transfer oil tube to achieve a steady temperature rising.

6. The valve adopts the pneumatic control system and is easy to operate.

Product Parameter

| Item | Specification | Unit | Remark | |

| General Parameter | Model | MTR10A | ||

| Name | Modified Emulsified Asphalt Equipment | |||

| Productivity | 10 | T/h | ||

| Total Power od Electrical Equipment | ≤71 | kw | ●Domestic Colloid Mill | |

| ≤71 | kw | ○Imported Colloid Mill | ||

| Dimension | 11000×2200×2500 | mm | ||

| Structure | Mobile Combination Structure | |||

| Oil-water Ratio | 5:5~6:4 |