Product Feature

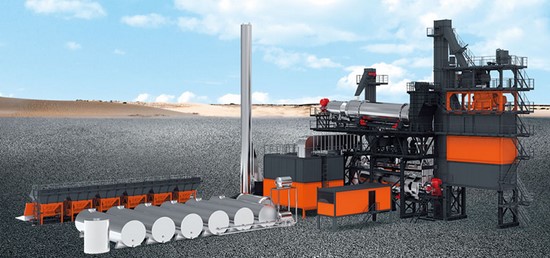

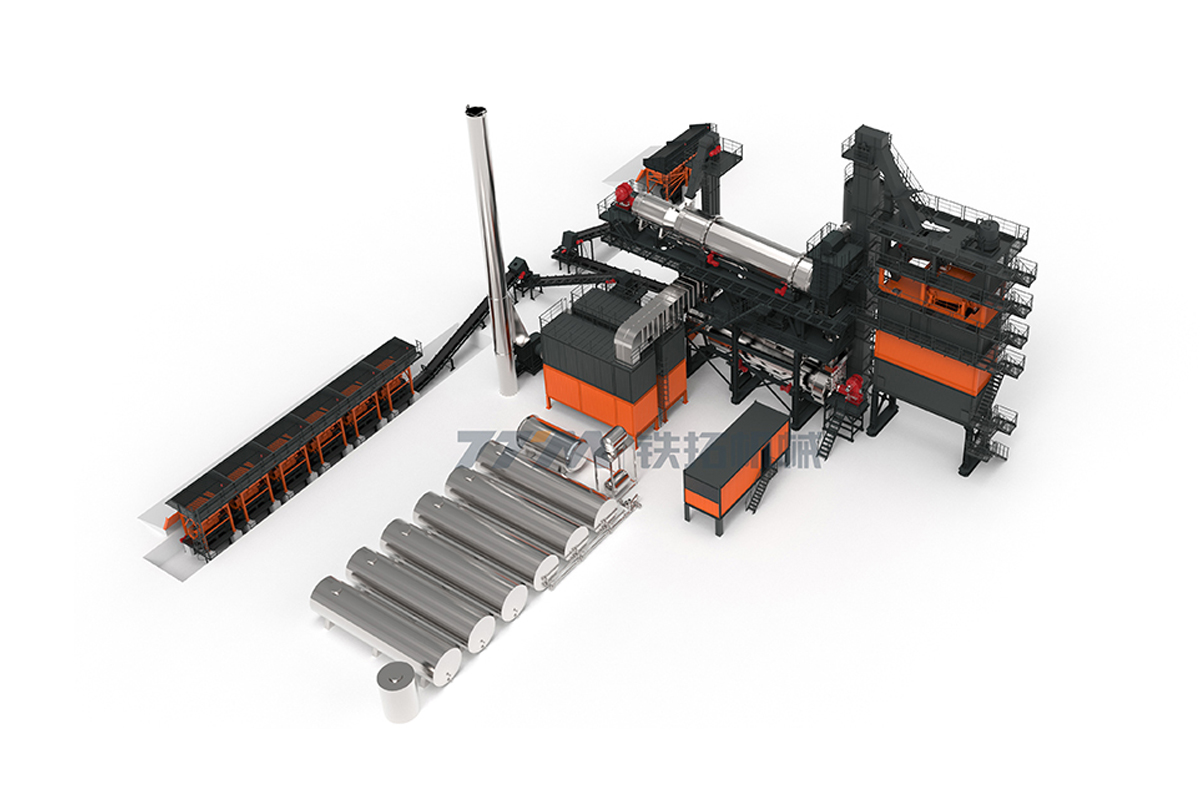

Counter-flow Asphalt Plant

The drum dryer operates on a counter-flow basis to achieve high heat efficiency and less fuel consumption. The drum is featured by large diameter, low rotation speed and small inclined angle, ensuring that the RAP material is heated gently in the rotating drum and less prone to aging. When the drum is rotating, the flights along its sides keep the aggregates tumbling without sticking and allow for self-cleaning.

Vertical Hot Air Generator

This hot air generator adopts vertical design with ceramic fiber linings, featuring extremely low heat absorption, less noise level, and easy to maintenance. The compact structure results in the shortened length of the equipment, thus providing high flexibility in space utilization and small footprint.

RAP Pre-mixing System

The pre-mixing system is used to mix RAP material with recycling agents. A manual switching unit is available to allow user to switch between pre-mixing and direct feeding freely. Material sticking and smoke issues can be efficiently avoided.

Large Capacity Mixer

The mixer is equipped with 4 gearboxes to provide sufficient power force. Dual-shaft mixing chamber with rational arrangement of paddles enables the mixing efficiency higher. The homogenous asphalt mixture can be quickly discharged through a rotating type discharge door.

Highlights of Environmental Protection

TSEC series eco-friendly asphalt recycling plant utilizes modular enclosed structure to prevent the spread of dust and loose particles to other work areas, and ergonomic sliding door enables operation easier. Dust control measures are adopted at cold feed bins, conveyor belt under bins and truck loading area, ensuring that the asphalt mixing plants meet the environmental compliance requirements.

Dust Control, Deodorization & Noise Reduction

Independently developed gas burner can meet the customer's requirement of clean-burning fuels;The flue gas will be transported to the burner for secondary combustion, thus preventing the asphalt flue gas from entering the atmosphere;Vent condensers are installed at vents of heavy oil and asphalt storage tanks to reduce blue smoke emissions. Optical oxygen catalytic and activated carbon adsorption can also be used for solving the problem of emissions.Cold feed system is fitted with pulse jet baghouse dust collector through ducting to remove dust generated during loading and conveying process;Reclaimed filler silo is fitted with wet mixing unit to reduce dust emissions;Foamed asphalt warm-mixing function efficiently reduce the smoke generated during the production process;Atomized mist unit can be configured to efficiently suppress asphalt dust at the site;Induced draft fan features blower sound enclosure, anti-vibration pads and duct silencer to reduce noise emission;Burner is equipped with high-efficiency silencer and sound enclosure to effectively control noise;Bucket elevator, vibrating screen and other equipment generating noise are all covered with aluminum-silicate wool insulated steel panel, providing optimal energy efficiency and noise reduction;

Product Parameter

Model | TSEC1510 | TSEC2015 | TSEC3015 | TSEC3020 | TSEC4020 | TSEC4030 | TSEC5030 |

Capacity of virgin aggregate (t/h) | 120 | 160 | 240 | 240 | 320 | 320 | 400 |

Capacity of RAP material (t/h) | 80 | 120 | 120 | 160 | 160 | 240 | 240 |

Recommended RAP ratio | 50% | 50% | 37.50% | 50% | 40% | 60% | 50% |

Capacity of virgin aggregate with RAP (t/h) | 140~160 | 200~240 | 280~320 | 280~320 | 360~400 | 440~480 | 480~520 |

Drum dryer model (virgin aggregate) | GT120 | GT160 | GT240 | GT320 | GT400 | ||

Dryer drum diameter (m) | 1.95 | 2.25 | 2.5 | 2.7 | 3 | ||

Dryer drum length (m) | 8 | 9 | 10 | 10 | 12 | 12 | |

Burner power (MW) | 11.8 | 19.7 | 21.3 | 27.8 | 35.5 | ||

Filtering area of baghouse (m虏) | 650 | 920 | 1200 | 1500 | 1940 | 1940 | |

Mixer capacity (kg) | 2000 | 3000 | 4000 | 5500 | 7500 | ||

Transmission of mixer | Double gearbox | Four gearbox | |||||

Drum dryer model (RAP material) | RGT80 | RGT120 | RGT120 | RGT160 | RGTC240 | ||

Dryer drum diameter (m) | 2.25 | 2.5 | |||||

Dryer drum length (m) | 8 | 10 | 12 | ||||

Burner power (MW) | 9.8 | 14.8 | 19.7 | 21.3 | |||

Combustion chamber (diameter脳length) | 酶1.8脳4.2 | 酶2脳4.2 | 酶2.5脳11 | ||||

Storage of RAP (t) | 9 | 12 | |||||

Capacity of RAP mixer (kg) | 1000 | 1500 | 2000 | 3000 | |||

Emission handling | Secondary combustion in the dryer of virgin materials | ||||||

RAP feeding to mixer | Direct feeding (mixer is installed beneath the RAP weighing system, without feed chute) | ||||||