Product Feature

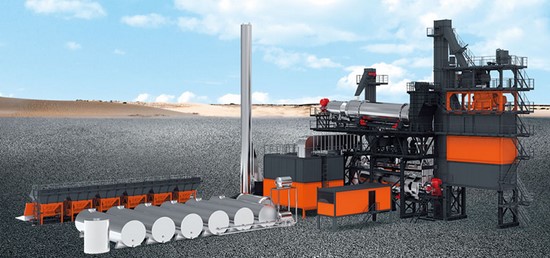

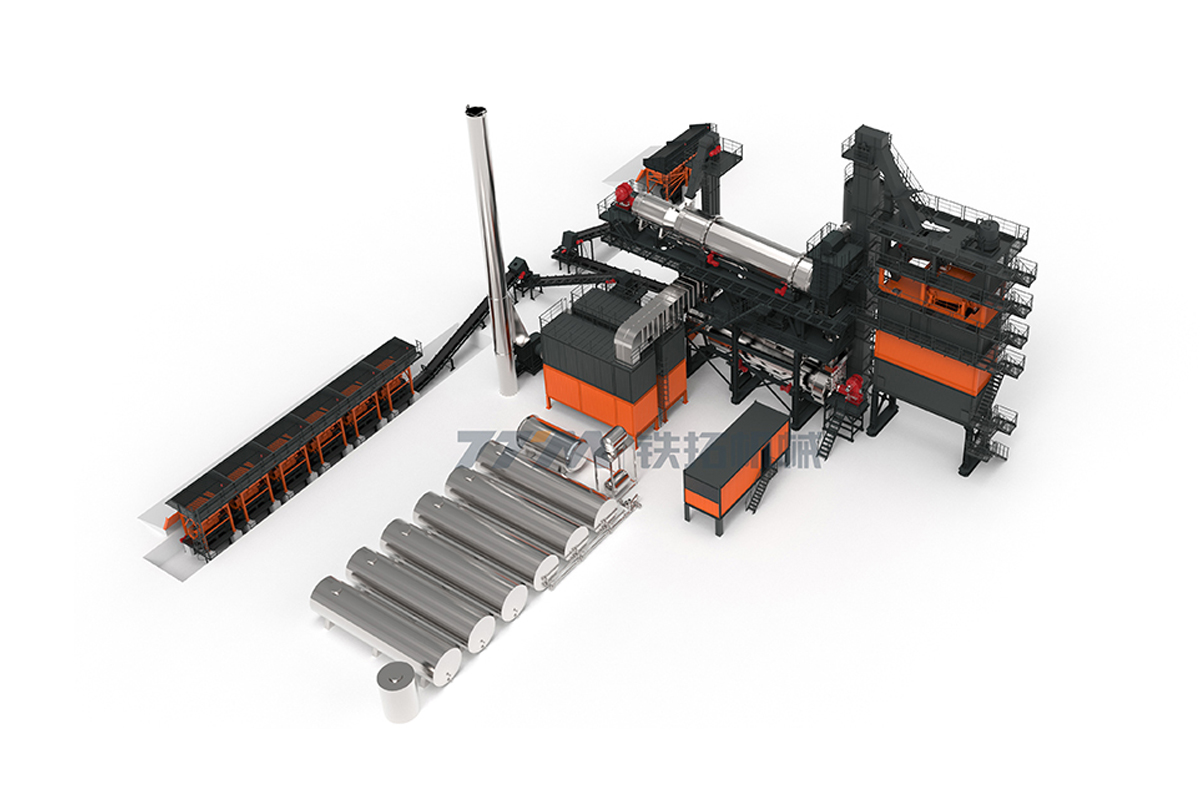

This series asphalt plant is our independently developed integrated hot mix asphalt recycling system to recycle reclaimed asphalt pavement (RAP) by mixing it together with virgin aggregates thereby enabling the reclaimed asphalt from old roads to be reused in an environmentally friendly way. The RAP recycling plant can not only solve environmental problems, but also help road construction companies lower their cost.

Since the mixer is installed beneath the RAP weighing system, which means the feed chute or belt conveyor are eliminated, so that this asphalt plant can solve the material blocking issues that may occur in RAP materials feed chute or belt conveyor. The integrated structure design provides optimal configuration of dust collection system and mixer, greatly improving production efficiency. The RAP recycling plant is configured with patented switching unit, allowing for switching between pre-mixing and direct feeding freely.

Highlights of Environmental Protection

- Energy Saving

All parts exposed to the atmosphere are covered with insulation layer to reduce heat losses;

Electric heating method is used as alternative to conventional thermal oil heating for asphalt storage;

Energy efficient motor reducer greatly reduces energy consumption;

Foamed asphalt warm-mixing function makes production process more energy efficient;

Dust Control & DeodorizationIndependently developed gas burner can meet the customer's requirement of clean-burning fuels;

The flue gas will be transported to the burner for secondary combustion, thus preventing the asphalt flue gas from entering the atmosphere;

Vent condensers are installed at vents of heavy oil and asphalt storage tanks to reduce blue smoke emissions. Optical oxygen catalytic and activated carbon adsorption can also be used for solving the problem of emissions.

Cold feed system is fitted with pulse jet baghouse dust collector through ducting to remove dust generated during loading and conveying process;

Reclaimed filler silo is fitted with wet mixing unit to reduce dust emissions;

Foamed asphalt warm-mixing function efficiently reduce the smoke generated during the production process;

Atomized mist unit can be configured to efficiently suppress asphalt dust at the site;

Noise ReductionInduced draft fan features blower sound enclosure, anti-vibration pads and duct silencer to reduce noise emission;

Burner is equipped with high-efficiency silencer and sound enclosure to effectively control noise;

Bucket elevator, vibrating screen and other equipment generating noise are all covered with aluminum-silicate wool insulated steel panel, providing optimal energy efficiency and noise reduction;

Product Parameter

Model | TSE1006 | TSE1510 | TSE2010 | TSE2015 | TSE3015 | TSE3020 | TSE4020 |

Capacity of virgin aggregate (t/h) | 80 | 120 | 160 | 160 | 160 | 240 | 320 |

Capacity of RAP material (t/h) | 48 | 80 | 80 | 120 | 120 | 160 | 160 |

Recommended RAP ratio | 40% | 50% | 33% | 50% | 37.50% | 50% | 40% |

Capacity of virgin aggregate with RAP (t/h) | 100~120 | 140~160 | 200~240 | 200~240 | 280~320 | 280~320 | 360~400 |

Virgin Aggregate | |||||||

Cold feed unit | The number of cold feed bins can be configured according to customer needs | ||||||

Number of hopper | 4 | 4 | 5 | 5 | 6 | 6 | 6 |

Volume of single hopper (m鲁) | 8 | 8 | 8 | 8 | 15 | 15 | 15 |

Drum dryer model | GT100 | GT120 | GT160 | GT160 | GT240 | GT240 | GT320 |

Dryer drum diameter (m) | 1.75 | 1.95 | 2.25 | 2.25 | 2.5 | 2.5 | 2.7 |

Dryer drum length (m) | 7 | 8 | 9 | 9 | 10 | 10 | 10 |

Dryer burner | Optional: diesel, diesel + heavy oil, coal powder, natural gas, oil + gas (as per customer's request) | ||||||

Burner power (MW) | 9.8 | 14.8 | 19.7 | 19.7 | 29.6 | 29.6 | 39.4 |

Dust collection system | Gravity+baghouse | ||||||

Filtering area of baghouse (m虏) | 510 | 650 | 920 | 920 | 1200 | 1200 | 1500 |

Number of hot bin | 4 | 5 | 6 | ||||

Volume of hot bin (m鲁) | 12 | 25 | 28 | 50 | |||

Mixer capacity (kg) | 1500 | 2000 | 3000 | 4000 | 5000 | ||

Transmission of mixer | Double gearbox with gear synchronization | ||||||

Finished asphalt storage | Under-storage/side-storage | ||||||

Volume of under-storage bin (t) | 100 | 200/300 | 200/300/400 | ||||

Volume of side-storage bin (t) | 100/200 | 200/300/400 | |||||

RAP Material | |||||||

Drum dryer model | RGT64 | RGT80 | RGR80 | RGT120 | RGT120 | RGT160 | RGT160 |

Dryer drum diameter (m) | 1.8 | 2.25 | 2.5 | ||||

Dryer drum length (m) | 8 | 8 | 10 | 12 | |||

Dryer burner | Diesel, diesel + heavy oil, natural gas, oil + gas | ||||||

Burner power (MW) | 5.9 | 9.8 | 14.8 | 19.7 | |||

Combustion chamber (diameter脳length) | φ1.6×3.8 | φ1.8×4.2 | φ2×4.2 | ||||

Storage of RAP (t) | 8 | 10 | |||||

RAP mixer | Optional | ||||||

Capacity of RAP mixer (kg) | 600 | 1000 | 1500 | 2000 | |||

Emission handling | Secondary combustion in the dryer of virgin materials | ||||||

RAP feeding to mixer | Feed chute or conveyor belt (optional) | ||||||

Total power (kW) | 90 | 110 | 160 | 160 | 185 | 185 | 200 |