Product Feature

● Efficiency and productivity

Increased efficiency with autoshift feature

After activation of the autoshift model,The machine will automatically upshift or downshift based on ground speed,This optimizes performance and therefore saves fuel。This feature can be easily enabled or disabled on the soft keyboard。

Deceleration pedal

The left pedal acts as a brake、Transmission Neutralizer and Engine Retarder,The engine speed selected by the throttle lock can be overridden。This allows the operator to decelerate with the throttle lock enabled,And does not need to be pressed again“Resume”Or“Set”Button to return to Throttle Lock Mode。This raises the machine in the truck.、Maneuverability when working around bulldozers or any other obstacles。

Steering and Transmission Integrated Control System(STIC™)

Steering and Transmission Integrated Control System(STIC,Steering and Transmission Integrated Control)The system selects the direction、Gear selection and steering operation integrated into a single lever,For optimum response and handling。

A simple sideshift action can steer the machine to the right or left.,Thus minimizing operator movement

Gear selection can be controlled by finger,The operation is very simple

By using a labour-saving integrated control device,Operation cycle is more stable、Fast,It also helps reduce operator fatigue

Steering system

824K The load-sensing hydraulic steering system of the enables precise machine control,Allows the operator to operate the machine with confidence。

Improved efficiency with variable displacement piston pump

43 degree steering articulation capability in each direction,Accurate position can be achieved in narrow area,Easy to load

Integrated steering and shift control for enhanced operator comfort

Electro-hydraulic control

Operators can take advantage of our responsive tooling capabilities to increase productivity。

Electronically controlled hydraulic cylinder stops for comfortable operation

Easy to use soft detent control

● Long-term value and durability

Solid construction

Very durable construction allows for multiple life cycles,And can handle the most demanding loading conditions.,Thereby improving your profitability。

The full box section rear frame can withstand strong torsional impact force and twisting force.

Heavy-duty steering cylinder mounts efficiently transfer steering loads to the frame

Optimized installation of axles,To enhance structural integrity

Dozer gp-push beam and push arm

To ensure longer service life and excellent reliability,Full-width solid integrated push beam,Not just attached to the side of the rack。When dozing at a corner,The stress is transferred and absorbed by the larger portion of the frame。

● Excellent performance

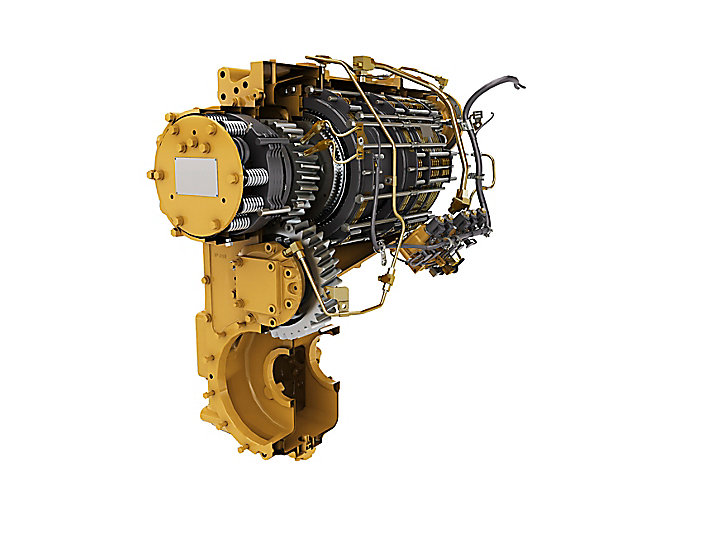

CAT Planetary Power Shift Transmission

A best-in-class transmission is your first step to success。

The integrated electronic control uses a single clutch transmission(SCSS),Uniformity can be achieved、Smooth shifting and greater efficiency。

Heat-treated gears and metallurgical techniques can extend service life and improve reliability。

Four forward speeds and four reverse speeds for your application。

With lock-up clutch CAT Torque converter(TC)

Avoid torque converter failure,While reducing system heat

Travel at a higher speed

Improve fuel efficiency

CAT C15 Engine

Cat C15 Engine goes through a rigorous manufacturing and testing proces,Ensure your most demanding applications are met。We offer two engine options:One that conforms to the United States. EPA Tier 4 Final/European Union Stage IV Emission standards,The other conforms to the United States. EPA Tier 3/European Union Stage IIIA Equivalent emission standards。

The fully integrated engine electronic control system works with the entire machine,Get more done with your fuel。

Using the Engine Idle Shutdown Function,Reduce fuel consumption at idle speed。

Using the Delayed Engine Shutdown Function,Maximize durability。

● Comfortable working

Our thoughtful cab features provide operator comfort,Work efficiently。

Cab access

Take advantage of these newly designed ergonomic features,It can be easy、Safe access to the cab。

Folding type STIC Steering device/Armrest

More gentle boarding ladder angle

Standard stairway lighting

CAT Comfort series III Chair

Cat Comfort series III The seat contributes to operator comfort,Reduce fatigue。

Center backrest design and extra thick contoured seat cushion

Air suspension system

Seat adjustment levers and controls are within easy reach,Six-way adjustable

Seat-mounted implement control box and move with seat STIC Steering device

76 mm(3")Wide retractable seat belt

Control Panel

Switch and message display ergonomically positioned,Keep the operator comfortable at all times。

A large-size backlight membrane switch has a structure that LED Activate the indicator lamp

The switch has ISO Symbol,Convenient and quick identification function

Two-position rocker switch activates the electro-hydraulic parking brake

Environment

We clean、Comfortable cab environment increases operator productivity。

Isolated cab mount and air suspension seat reduce vibration。

The automatic temperature control device keeps the cab at a suitable temperature.。

Pressurize the cab with filtered air

Reduced noise level

Convenient floor-standing tray/Lunch box

● IntegrationCATETechnology

Cat Connect Intelligent use of technologies and services to improve jobsite efficiency。By analyzing the data provided by a machine equipped with this technology,,You can be more comprehensive than ever、Gain insight into your equipment and operations。Cat Connect The technology has been improved in the following main aspects:Equipment management – Extend machine uptime,Reduce operating costs。Safe – Improve the safety awareness of the work site to ensure the safety of personnel and equipment。

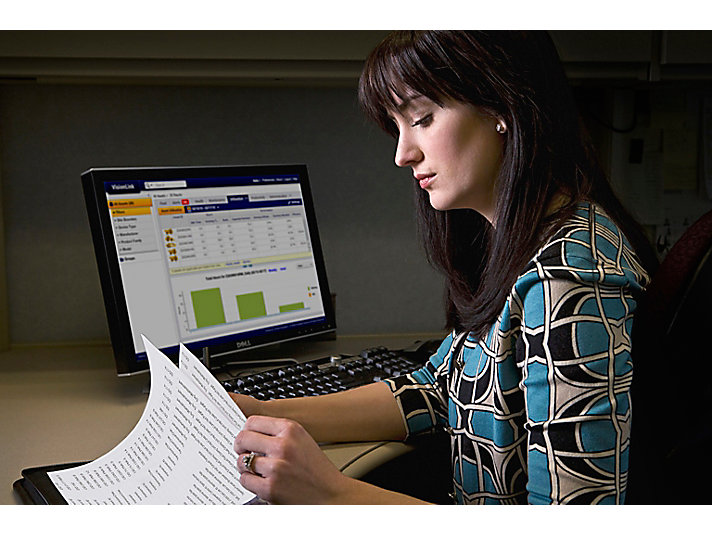

LINK Technology

Product Link™ Etc LINK Technology can help you connect to your devices wirelessly,Provides you with important information about the working condition of your machine or fleet。Through online VisionLink® Interface to track the location of the machine、Number of hours worked、Fuel consumption、Idle Time and Event Code,You will be able to make timely decisions based on the actual situation,Thereby improving the efficiency and productivity of the job site.,While reducing operating costs。You can download and analyze event、Histograms, historical trends, etc. VIMS™ Data,Obtain the necessary information,This proactively keeps the fleet up and running and optimizes machine performance and uptime。

DETECT Technology

Rearview camera head DETECT Technology expands your view of the environment around your work equipment,Gives you a better understanding of your surroundings,So as to work with confidence to the fullest potential.。

● Save on repair and maintenance costs

824K The machine incorporates a number of design features designed to reduce downtime,Help you succeed。

Ground or platform access and centralized maintenance points facilitate safe maintenance。

Swing-out doors on both sides of the engine compartment make it easy to perform important daily service check。

Ecological outfall helps simplify maintenance,And prevent potential environmental contaminants from escaping。

With the help of important information management system(VIMS,Vital Information Management System)Notice of,Operators and service technicians can fix any problems before they occur,This reduces downtime。

Sight gauge allows quick visual inspection and minimizes fluid contamination。

Swing out fuel、Hydraulic oil cooler and condenser for easy cleaning。

Ground level electrical service center with electrical disconnect switch、Engine emergency stop switch and stairway lighting switch。

The optional tire pressure monitoring system provides real-time information to the operator in the cab,This ensures proper tire inflation pressure and optimizes tire life。

Illumination in the engine compartment for better visibility of service points。

● Top service and support

It has a long reputation CAT Dealer support

Cat The agent is your right partner.,Ready to meet your needs。

Preventative maintenance program and guaranteed maintenance contract

First-class parts supply

Improve your efficiency by training your operators

Cat Original remanufactured parts

● Safety first

We are constantly improving our products.,Strive to provide a safe working environment for operators and field workers。

Machine access

Boarding stairs on the left and right sides raise the operator up and down 824K Security of。

Service area with handrail and non-slip surface with foot pedal,Allow staff to pass through smoothly。

The maintenance area can be reached from the ground or from a platform,Always maintain three points of contact。

View

The optional rear view camera and in-cab monitor enhance the operator's knowledge of the machine's surroundings。

Standard for cab mounting LED Warning strobe light

Operator environment

Isolated cab mount,And seat-mounted implement and steering control,Reduces vibrations transmitted to the operator。

Low internal noise level

Pressurize the cab with filtered air

The operator seat is equipped with a standard 76 mm(3")Seat belts

Show less information

● Reduce the impact on the environment

Reduce environmental impact

824K Sustainability in design and manufacturing。

The engine idle shutdown feature prevents unnecessary idling,Helps save fuel。

Use of maintenance-free battery,Can reduce waste discharge。

Cat 824 has multiple lifecycles,It is one of the most renovated products,The second and third service life can be realized.,So you get the most out of your investment.。To maximize the service life of the machine,Caterpillar Many sustainability options available,Such as remanufacturing and Certified Rebuild(Certified Renovation)Plan。In these plans,Cost savings on reused or remanufactured components 40% To 70%,It not only reduces the operation cost,,It is also beneficial to the environment.。

Caterpillar Complete renovation available,Bring new features to old machine,Maximize your resources。In addition,When you implement Cat When the renovation plan is certified,These refurbishment kits are part of the refurbishment process。

Show less information

● Specially madeCATTooling

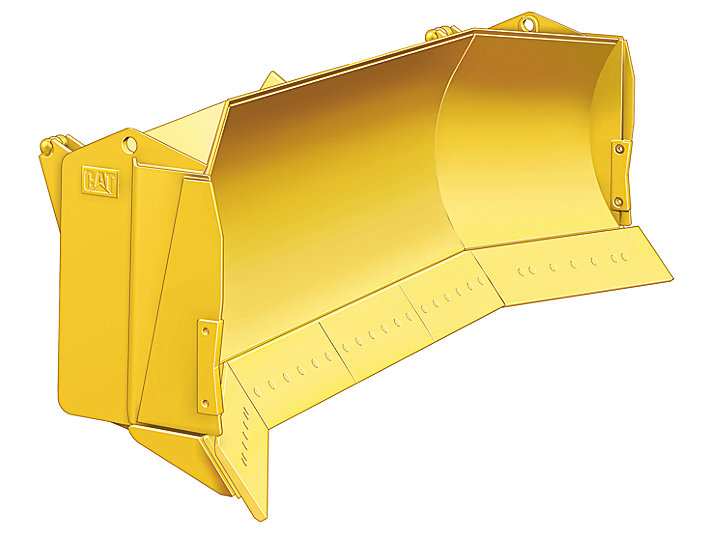

CAT Blade

Cat The blade is durable,Excellent dozing and turning performance。

Capacity and width are carefully set,Higher productivity can be achieved。

Spreading design allows spreading of cover material and dozing of heavy loads。

Straight shovel

Straight shovel(5.0 m3/6.6 yd3)For dozing in stockpiling and general earthwork。

U Shovel

U Shovel(7.7 m3/10.0 yd3)For moving large loads over long distances in mining applications。

SU Shovel

SU Shovel(7.7 m3/10.0 yd3)Combines straight shovels with U The characteristics of the shovel。It was retrofitted with short wings.,Capacity increase,But with only the bulldozer end edge on the short wing plate,Without sacrificing the paving characteristics of the straight blade.。

Coal Shovel

Coal Shovel(16.2 m3/21.1 yd3)Have more capacity,Suitable for loading light materials,It is capable of performing accurate and productive dozing operations,While helping to maintain load control。The angle of the wing helps to maintain the load during dozing。

Component

These blades and push arm、Hydraulic lifting device、Tilt cylinder、Trunnion mounting、Blade components such as the stabilizer bar and the hydraulic tube guard are assembled together。

Extended Life Abrasive Bulldozer Arrangement

Extended Life Abrasive Bulldozer Arrangement Designed to move large loads over long distances in demanding applications。It consists of a cutting edge、Push arm、Integrated cylinder guard、Heavy-duty stabilizer bar and front and sides are made of wear-resistant material (ARM) 8.1 m3/10.7 yd3 U Shovel composition。

Other options

About Other Blade Option,Please talk to your Cat Agent contact。

● And that fuel cost is save

And that fuel cost is save

Data from the client machine indicates that,Cat Wheeled tractors are among the most fuel efficient in the industry。This excellent fuel efficiency is due to the following features:

Engine – Advanced engine controls for optimum power and efficiency。

Engine idle shutdown – Automatic engine and electrical system shutdown reduces fuel consumption。

Lock-up torque converter – Delivers more traction and optimizes fuel efficiency in all applications。

Single-clutch transmission(SCSS)– Brand new SCSS Transmission control provides more power on grades,And can smoothly shift gears to save fuel。

The fuel tank has the capacity to support at least 12 hours of operation,Depending on the application。

Configuration of the machine、Fuel consumption is influenced by the skill of the operator and the layout of the job sit。

Machine configuration – Select the correct blade configuration for your application。

Product Parameter

ENGINE |

|

Engine model |

Cat® C15 |

Net power - ISO 9249 |

302 kW |

Stroke |

171.4 mm |

Discharge |

In line with the United States EPA Tier 4 Final/Ooh Alliance Stage IV Emission standards, Or conform to the United States EPA Tier 3/Ooh Alliance Stage IIIA Equivalent emission standards |

Displacement |

15.2 l |

Cylinder bore |

137.2 mm |

Engine |

|

Total power |

324 kW |

Gearbox |

|

Type of transmission |

Planets – Power shift – ECPC |

Axle |

|

Front |

Planets - Fixed |

Rear |

Planets – Swing |

Swing angle |

±11° |

Maintenance refill capacity |

|

Differential - Final drive - Front |

100 l |

Differential - Final drive - Rear |

110 l |

Gearbox |

66 l |

SERVICE REFILL CAPACITIES |

|

Fuel tank |

782 l |

Cooling system |

116 l |

Working specifications |

|

Operating weight |

34004 kg |

Size(Approximate value) |

|

Height - Top of the hood |

3204 mm |

Height of top of cab |

4100 mm |

Wheelbase |

3700 mm |

Centerline of rear axle to bumper edge |

2830 mm |

Height - Top of the exhaust pipe |

4332 mm |

Ground clearance |

441.4 mm |

Centerline of front axle to hitch |

1850 mm |

Hydraulic system |

|

Double acting cylinder |

Roll and Tilt Bore and Stroke |

Double acting cylinder - Promote、Bore and stroke |

120 mm × 1070 mm(4.7" × 42.1") |

Hydraulic system - Turn |

|

Steering system - Loop |

Double Action – Mounted at the end |

Steering system - Pump |

Piston – Variable displacement |