Product Feature

● Achieve the lowest possible cost of ownership

Design concept:CAT Large bulldozer

Ensure high productivity in all applications

Ensure operator safety, comfort and efficient operation

Make the most of technology

For easy maintenance and repair

Ensure durability

● Bulldozers for your application

High productivity in any application:

Overhead sprocket and suspended undercarriage work together:

Increase traction,Enables the operator to have a smooth driving experience in all conditions

Make the components easy to remove,Thereby reducing maintenance time.

Overhead sprockets transmit implement impact loads to the main frame,Make the final drive、Axles and steering components are protected from strong impact

Application

Overburden split soil

Production bulldozing

Reclamation

Winch towing

Device cluster support

Site maintenance

Stacking

● Improve the efficiency of dozing operation

Improve performance and efficiency

Torque converter with stator clutch - High efficiency,Low fuel consumption

Bogie suspension - Not easy to slip,Higher productivity

Differential steering - Large load,Fast and smooth handling

Not easy to slip,The yield is increased

D9 Use bogie suspension device,Conform track to ground condition,The ground area can be increased,Pecially on rough, hard ground.。Higher traction means less slip、The balance is higher、The ride is smoother。

Large load,Smooth handling。

D9With differential steering,Large blade loads can be moved smoothly with one turn。The differential provides a compact turning radius.,Can maintain high travel speed during cornering to maintain high productivity。The planetary power shift transmission is available through the Advanced Productivity Electronic Control System(APECS,Advanced Productivity Electronic Control System)Achieve smooth speed and commutation。

Torque converter with stator clutch

1)Under low load condition,When no torque increase is required,Automatically release the stator,Thus:

– Increase the efficiency of the power train

– Reduce fuel consumption

2)Automatic locking during higher loads and deceleration

3)The operator will not perceive a significant change in the display of less information

● Safe and sound

Increased safety for operators and service personnel

360-degree visual system(Optional)

Flashing orange marker lights and LED Lighting(Optional)

Improved cab boarding ladder,Cab door with front hin(Optional)

Operate the engine shutdown aid switch

Continuous level monitoring

Auxiliary fixing on articulated belly guard

Improved cab,With new seats and HD touch screen monitor

Electric escalator(Optional)

Notched fuel tank and narrow ripper frame,Make sure you have a clear line of sight

Preparation for fire extinguishing system — Bottle mounting bracket(Optional)

● Operator environment

An incomparable cab

Enhanced ergonomics(Throttle control,One screen instead of many,Optional boarding ladder is available)

Fully adjustable air suspension seat(Heating/Refrigeration)

Labor-saving electronic gearbox、Turn、Ripper and Dozer Control

Automatic temperature control

Designed for comfort

Save effort,Reduce noise and vibration

Suspension undercarriage absorbs shock,Reduce the impact load,Keep the track grounded

Increased productivity

Larger information display、Faster、The effect is better

High-definition color touch screen

In-car 41 languages

Fewer buttons and screens in the cab — Intuitive Operator Setup Menu

Individual light control

Provide real-time feedback on tractor performance

Work monitor screen(Optional)Helps operators maximize productivity

● Innovation

Technology:Support future applications

Seamless integration with optional machine control and guidance systems:

Blade Auto Assist(ABA)

AutoCarry

Automatic Ripper Control

Grade Control 3D

● CATBlade and tooling

CAT Blade:Perfect match

Easily handle hard-to-handle material

Excellent load capacity

Resistance to torsional bending and twisting

Improve wear resistance and bulldozing efficiency,Without degrading machine balance or performance

Blade option

Universal type(U)

Semi-universal type(SU)

Professional tooling

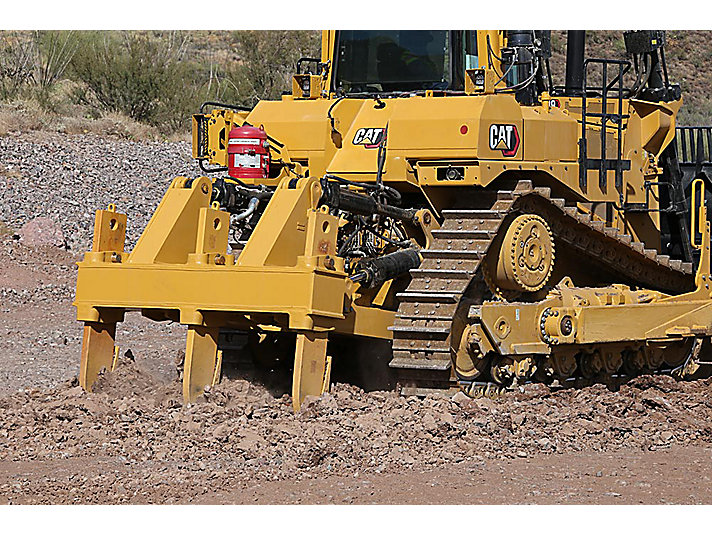

Single Shank Ripper

Multiple Shank Ripper

● DURALINKMChassis system

DURALINK™ Chassis system

Use the new heavy load for a long time.(HDXL,Heavy-duty Extended-life)Chassis system,Extends undercarriage life by 20 percent-40%,Seal life of 8000 hours achieved

● Reduce downtime

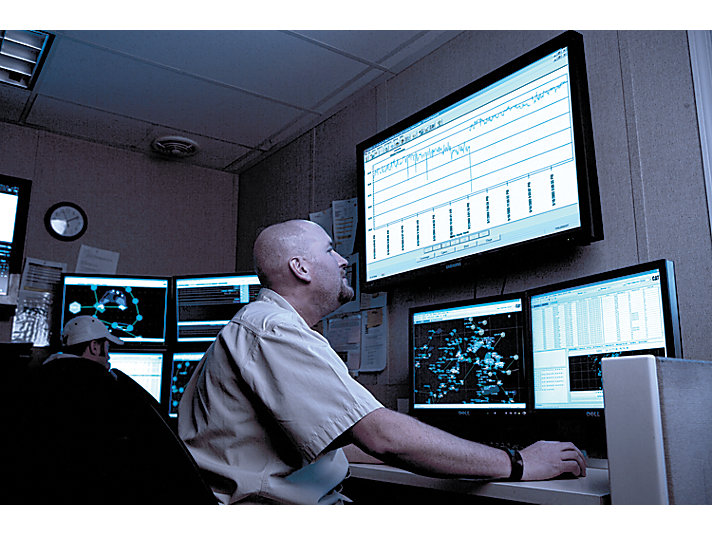

COMMAND FOR DOZING

Multi-level remote control operation

Over the shoulder remote control console

Remote console

Gives the operator full control of the dozer,Without being exposed to dust.、Noise、Effects of vibration or other hazards

● Support

Support Network

Yours Cat Dealers know how to keep your machine running.。We have established an extensive network of nearly 200 local enterprises in more than 200 countries or regions.。So,No matter where you are,Our agents will be close to you. Cat Equipment provides world-class service and support。

Product Parameter

Engine - America EPA TIER 2/3 Equivalent Standards |

|

Engine model |

Cat® C18 |

Net engine power - SAE J1349/ISO 9249 |

337 kW |

Cylinder bore |

145 mm |

Stroke |

183 mm |

Displacement |

18.1 l |

Total engine power - SAE J1995 |

363 kW |

Engine power - ISO 14396 |

357 kW |

Discharge |

America EPA Tier 2 |

Note(1) |

All engine ratings are at |

Note(2) |

Elevation below 4267 m(14000 ft) |

Engine - America EPA TIER 4 FINAL/European Union STAGE V |

|

Engine model |

Cat® C18 |

Cylinder bore |

145 mm |

Stroke |

183 mm |

Displacement |

18.1 l |

Total engine power - SAE J1995 |

356 kW |

Engine power - ISO 14396 |

349 kW |

Net engine power - SAE J1349/ISO 9249 |

328 kW |

Discharge |

America EPA Tier 4/Ooh |

Note(1) |

All engine ratings are at |

Note(2) |

Altitude up to 2499 m(8200 ft) |

Fluid capacity |

|

Fuel tank(Anti-splash fill) |

963 l |

DEF Box(Only Tier 4) |

36 l |

Fuel tank(Quick fill) |

939 l |

Cooling system |

81.3 l |

Engine crankcase* |

36 l |

Power train |

150 l |

Final drive(Each) |

15 l |

Roller frame(Each) |

45 l |

Pivot shaft oil |

30 l |

Hydraulic system tank |

89 l |

Remark |

*With oil filter。 |

Note 2 |

Can also be used with 15 ppm(mg/kg)Sulphur |

Note 3 |

All non-roads Tier 4 Final |

Note 4 |

Cat Selective catalytic reduction for Standardization) Requirements specified in the standard 22241.。 |

Weight |

|

Operating weight |

49988 kg |

Shipping weight |

38271 kg |

Note(1) |

D9Operating weight includes hydraulic control、 |

Note(2) |

D9Operating weight includes base machine undercarriage |

Hydraulic control unit |

|

Pump type |

Piston type flywheel drive |

Pump output - Turn |

363 l/min |

Fan pump |

80 l/min |

Tilt cylinder flow – Rod-end flow |

200 l/min |

Tilt cylinder flow – Cylinder head flow |

200 l/min |

Lift Cylinder Relief Valve Settings |

26200 kPa |

Tilt Cylinder Relief Valve Settings |

19300 kPa |

Ripper - Promote - Relief valve settings |

26200 kPa |

Ripper - Flat and oblique - Relief valve settings |

26200 kPa |

Steering system - Pressure |

40500 kPa |

Fuel tank capacity |

89 l |

Note(1) |

At 1750 rpm Engine speed and |

Note(2) |

At 1750 rpm Engine speed and |

Note(3) |

At 1750 rpm Engine speed and |

Chassis system |

|

Type of track shoe |

Extreme operation |

Width - Shoe |

610 mm |

Number of track shoes per side |

43 |

Grouser height |

84 mm |

Pitch |

240 mm |

Ground clearance |

459 mm |

Track gauge |

2250 mm |

Length - Grounding track |

3470 mm |

Ground area |

4.23 m² |

Number of track rollers per side |

8 |

Number of carrier rollers |

1 per side(Optional) |

Steering and braking system |

|

Steering type |

Differential |

Braking type |

Spring pressure type wet disc |

Brake diameter |

393.7 mm |

Brake count |

8 |

Air conditioning system |

|

Air conditioner |

The air conditioning system on this machine consists of |

Standard |

|

ROPS |

Roll-over protection structures |

FOPS |

Anti-falling object protective structures(FOPS)Conform |

Noise |

When used ISO 6395:2008 measurement |

Noise(1) |

Use ISO 6396:2008 Measurement closed type |

Noise(2) |

When using an open console for an extended period of times、 |

Gearbox |

|

1.0 forward |

3.5 km/h |

2.0 forward |

6.3 km/h |

3.0 forward |

11 km/h |

1.0 reverse |

4.4 km/h |

2.0 reverse |

7.8 km/h |

3.0 reverse |

13.6 km/h |

Type |

Planetary power shift |

Blade - Semi-universal |

|

Blade capacity(SAE J1265) |

13.6 m³ |

Blade width(With end blade) |

4350 mm |

Blade height |

1934 mm |

Maximum excavation depth |

606 mm |

Ground clearance at full lift |

1422 mm |

Maximum inclination |

940 mm |

Blade weight |

4802 kg |

Total operating weight*( Ripper with blade and single shank) |

49988 kg |

Remark |

* Total operating weight including |

Blade - Universal |

|

Blade capacity(SAE J1265) |

16.6 m³ |

Blade width(With end blade) |

4680 mm |

Blade height |

1934 mm |

Maximum excavation depth |

606 mm |

Ground clearance at full lift |

1422 mm |

Maximum inclination |

1014 mm |

Blade weight |

5450 kg |

Total operating weight*( Ripper with blade and single shank) |

50513 kg |

Remark |

*Total operating weight including |

Ripper - Single toothed bar |

|

Maximum penetration*(Vertical toothed bar) |

158 kN |

Maximum penetration depth(Standard tip) |

1231 mm |

Digging force |

332 kN |

Maximum lifting clearance - At the tip of the tooth Below,Fixed in the bottom hole |

882 mm |

Number of slots |

1 |

Weight |

4854 kg |

Total operating weight* (Belt SU Shovel and noted ripper) |

49988 kg |

Remark |

*Total operating weight including |

Ripper - Single toothed bar,Deep Ripping |

|

Maximum penetration*(Vertical toothed bar) |

172 kN |

Maximum penetration depth(Standard tip) |

1727 mm |

Digging force |

331 kN |

Maximum lifting clearance - At the tip of the tooth Below,Fixed in the bottom hole |

817 mm |

Number of slots |

1 |

Weight |

4981 kg |

Total operating weight* (Belt SU Shovel and noted ripper) |

50115 kg |

Remark |

*Total operating weight including |

Ripper - Multi-toothed bar, Adjustable parallel link |

|

Maximum penetration - Vertical toothed bar |

154 kN |

Maximum penetration - Standard tip |

798 mm |

Digging force - Multidentate cleft Earthen implement,With a tooth |

361 kN |

Maximum lifting clearance - At the tip of the tooth Below,Fixed in the bottom hole |

879 mm |

Number of slots |

3 |

Weight |

5550 kg |

Total operating weight* - Belt SU Shovel and Ripper |

50684 kg |

Remark |

* Total operating weight including |

Winch |

|

Winch model |

PA 140VS |

Weight* |

1790 kg |

Oil capacity |

15 l |

Drum width |

320 mm |

Recommended Cable Diameter |

28 mm |

Optional cable diameter |

32 mm |

Maximum drum capacity - Recommended cable length |

78 m |

Maximum drum capacity - Optional cable length |

62 m |

Cable ferrule specification - Outside diameter |

60 mm |

Cable ferrule specification - Length |

70 mm |

Remark |

*Weights shown are for the base winch only。 |

Note(2) |

Variable speed,Hydraulic drive,Double braking |

Size(Approximate value) |

|

Ground clearance* |

459 mm |

Track gauge |

2250 mm |

Width - Trunnions are not included - Standard track shoes |

2870 mm |

Width - Includes a trunnion |

3310 mm |

Height - FOPS Cab* |

3820 mm |

Height - Top of the exhaust pipe* |

3876 mm |

Height - ROPS/Roof* |

4000 mm |

Drawbar height(U Center of the clamp)* |

763 mm |

Length - Grounding track |

3470 mm |

Overall Length of Basic Dozer |

4910 mm |

Length - Basic configuration bulldozer - Drawbar included |

5242 mm |

Length - Basic configuration bulldozer - Capstan included |

5545 mm |

Length - Belt SU Shovel** |

6601 mm |

Length - Belt U Shovel |

6967 mm |

Length - Ripper with single shank |

6529 mm |

Length - Ripper with multiple rack |

6538 mm |

Total length - SU Shovel/SS Ripper |

8219 mm |

Note(1) |

*For those measured on hard ground |