Product Feature

● Structure

Solid construction

Very durable construction allows for multiple life cycles,And can handle the most demanding loading conditions.,Thereby improving your profitability。

The full box section rear frame can withstand strong torsional impact force and twisting force.。

Castings in the engine end frame may be used in areas of high stress to distribute high loads。

Cast pivot mounting area for better load distribution,Increase structural integrity。

90% The structural parts of the machine are automatically welded.,The welds are extremely uniform,The strength is improved。

Rack

Our purpose-built front and rear racks are key to maximizing uptime and productivity。

The frame with full box section design can absorb the torsional force generated during bulldozing.,Align the coupling pin with the driveline。

Spread out hitch design with double tapered roller bearings and hardened pin,Capable of withstanding horizontal and vertical loads。

One-piece casting for key pin joint,The structural strength is enhanced.。

Dozer gp-push beam and push arm

To ensure longer service life and excellent reliability,Full-width solid integrated push beam,Not just attached to the side of the rack。When dozing at a corner,The stress is transferred and absorbed by the larger portion of the frame。

● Power train

Impeller clutch torque converter(ICTC)And rimpull control system(RCS)

Adopt advanced ICTC And RCS To flexibly adjust rimpull,Thus reducing your cost per ton。

When the left pedal is depressed,The rimpull can be increased from 100% Adjust to 25%,Thus reducing tire slip and wear。At 25% After rimpull,The left pedal applies the brake。

RCS The possibility of wheel slip is reduced without reducing the efficiency of the hydraulic system。

Provides direct drive with our lock-up clutch torque converter,Can improve fuel efficiency in some application。

Steering and Transmission Integrated Control System(STIC™)

Steering and Transmission Integrated Control System(STIC,Steering and Transmission Integrated Control)The system selects the direction、Gear selection and steering operation integrated into a single lever,For optimum response and handling。

A simple sideshift action turns the machine to the right or left.,Thus minimizing operator movement。

Gear selection can be controlled by finger,The operation is very simple。

By using a labour-saving integrated control device,Operation cycle is more stable、Fast,It also reduces operator fatigue.。

CAT Planetary Power Shift Transmission

Best-in-class gearboxes designed for mining operations are your first step to success。

The integrated electronic control device can realize the uniformity、Smooth shifting and greater efficiency。

Heat-treated gears and metallurgy for longer service life and increased reliability。

Three forward speeds and three reverse speeds,Effectively meet operational needs。

CAT C32 ACERT Engine

By virtue of adoption ACERT Technical Cat C32 engine,854K Excellent durability and efficiency。It has a 12-cylinder four-stroke design.,Achieve optimal performance。

With turbocharger and aftercooler,On-demand performance。

High torque reserve — 33% A torque reserve,Ensures high traction during stacking operation。

Use a lower speed rating,And prolong that service life of the engine.。

Fast engine response through the use of the engine electronic control system。

America EPA Tier 4 Final Power rating for areas with strict emission restrictions。

● Hydraulic system

Electro-hydraulic control

Operators can increase productivity with our responsive implement features。

Electronically controlled hydraulic cylinder stops for comfortable operation。

Easy to use soft detent control,The operation is more convenient。

The blade responds

Improves operator efficiency by matching blade movement speed to application。

Three different speeds:Standard、Fine and fast。

Through Advisor The display is easy to configure。

Only affects the blade lift function。

Steering system

854K The load-sensing hydraulic steering system of the enables precise machine control,Allows the operator to operate the loader with confidence。

Increased efficiency with variable displacement piston pump。

43-degree steering articulation allows precise positioning in tight areas,Easy to load。

Integrated steering and transmission control for enhanced operator comfort。

Filtration system

Our advanced filtration system enhances the performance and reliability of your hydraulic system。

Promote/Tilt Case Drain Filter。

Promote/Tilt the high pressure screen。

Steering Case Drain Filter。

High pressure strainer for steering。

Hydraulic Case Drain Filter。

Front Pump Drive Lube Oil Filter。

Front and rear brake oil screens。

● Console

Our thoughtful cab features provide operator comfort,Work efficiently。

In and out

With these newly designed ergonomic features,Easy and safe access to the cab。

Boarding points on both sides。

Folding type STIC Steering device/Armrest。

More gentle boarding ladder angle。

CAT Comfort series III Chair

Cat Comfort series III Seat enhances operator comfort,The degree of fatigue is reduced。

High backrest design and extra thick contoured seat cushion。

Air suspension system。

Levers and controls for the seat are within easy reach,Adjustable in six directions。

Seat-mounted implement control box and move with seat STIC Steering device。

76 mm(3 in)Wide retracting seat belt。

Trainer seat

Equipped with standard trainer seat,Train other operators in safety and comfort。

76 mm(3 in)Wide retracting seat belt。

Fold-down design,With molded beverage tray and storage area。

Environment

We clean、Comfortable cab environment increases operator productivity。

Viscous cab base and air suspension seat reduce vibration。

The automatic temperature control device keeps the cab at a suitable temperature.。

Pressurize the cab with filtered air。

Noise level reduced to a quiet 71 dB(A)。

● Technical solutions

Fully integrated 854K Electronic system,Works as one machine。This integration makes the machine more intelligent.,And give the operator a more complete view of machine operation,Thereby maximizing the productivity of both.。

VIMS™ 3G

We have been through the important information management system.(VIMS 3G)Strive to help customers and operators achieve peak performance。

Easy to view Advisor Display has a large screen size。

Improved user interface for intuitive operation,Navigation is simple。

Shorten service time by making the operator aware of machine system problems or operating conditions。

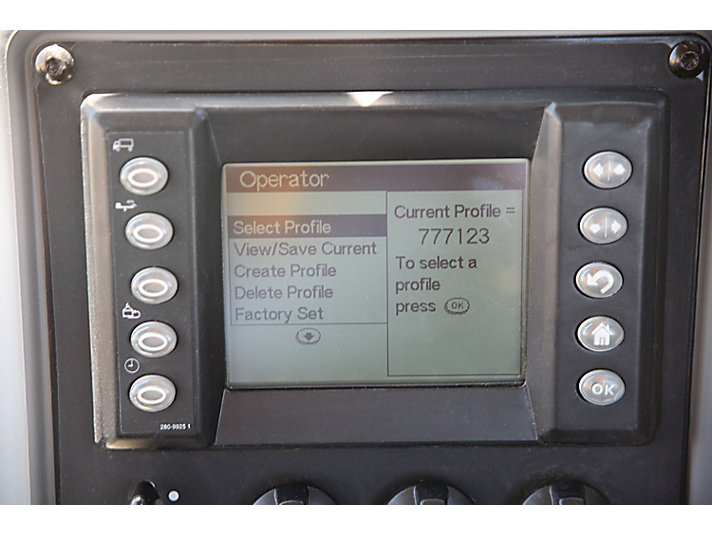

Operator profile

Operator comfort comes from individual machine function settings。Through Advisor Display screen,Personalized profiles are instantly available to the operator。

Advisor Up to 10 different operator profiles can be stored in。

By invoking a personalized screen layout,Shorten setup time when changing operators。

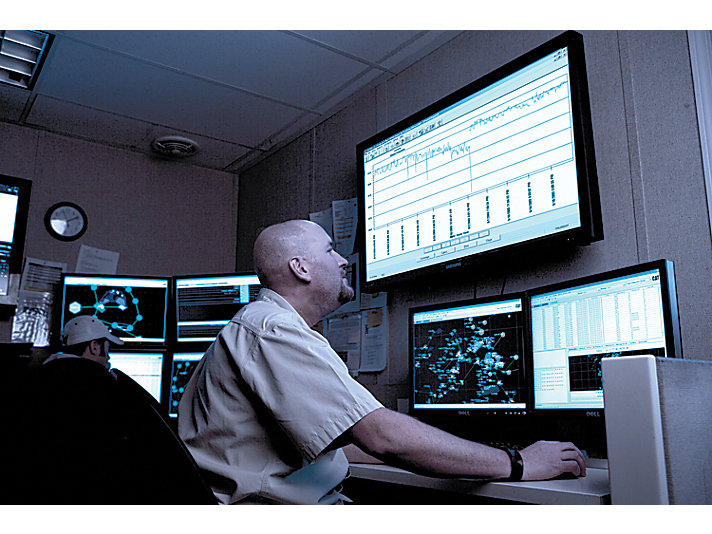

● CAT MINESTAR SYSTEM

Cat MineStar System The most comprehensive system in the industry,It integrates mine operation technology and mobile device management technology.,Flexible configuration according to specific operation requirements。Its suite of features - Fleet、Terrain、Detect、Health And Command Contains a range of technologies,Make it easy for you to handle everything:Whether it's device fleet allocation and status monitoring,Or remote and automatic control。854K Some of these advanced technologies are used.,Some have become standard factory configuration。

CAT FLEET

Fleet(The motorcade)Kits provide full real-time machine tracking、Vehicle allocation and productivity management,Gives you a comprehensive view of all jobs around the world。

TERRAIN FOR LOADING

854K Equipped Terrain(Terrain)The kit manages loading operations with high precision through the use of guidance technology。It improved by 854.K Productivity,And provide you with real-time feedback to improve efficiency。

DETECT

Detect The system helps increase operator safety awareness,Thereby improving operational safety.。It includes a range of features.,Designed to assist the operator in observing restricted areas around fixed and mobile equipment。

HEALTH(Health status)

Health The kit displays critical machine status information by event,And display the operation data of the whole equipment cluster。It has complete equipment health and asset monitoring capabilities,And contains a series of diagnostic、Analysis and reporting tools。

● Safe

We are constantly improving our products.,Strive to provide a safe working environment for operators and field workers。

Machine access

A wider boarding ladder with a more gradual angle ensures that the operator can get on and off the 854 safely.K。

The maintenance area is designed with surface anti-skid walkway and integrated locking./Signing point。

The windshield cleaning platform allows the operator to perform servicing safely and easily。

The maintenance area can be reached from the ground or from a platform,Always maintain three points of contact。

Emergency exit。

View

Optional pull-down window shades and optional heated mirrors for increased visibility,Ensure safe operation。

Cat Detect Equipped with target detection system(Rear view camera and radar)Or Vision(Rear view camera)Optional,Increased operator awareness of the machine's surroundings。

Standard HID Lamps provide excellent visibility of the work space。

The cab is fitted with LED Warning beacon light。

Operator environment

Viscous cab base and air suspension seat reduce machine vibration to the operator。

Low internal noise level。

Trainer seat facilitates safe training of new operators。

Standard 76 on Operator Seat and Trainer Seat mm(3 in)Seat belt。

Electric boarding system

Cat An electric boarding system improves access to the rear platform,Make the main ladder more accessible to the operator。

Ergonomic safety boarding system。

Use wide stairways,Ample space for operators of all sizes。

When using the handrails on each side,The operator can always maintain three-point contact。

The platform can be raised or lowered from cab height or the ground。

If there is a problem with the loader,The operator can quickly evacuate with the aid of the nearby emergency release valve。

● Convenient maintenance

854K Loaders incorporate a number of design features designed to reduce downtime,Help you succeed。

Longer maintenance intervals for fluids and filter。

Ground or platform access and centralized maintenance points facilitate safe maintenance。

Swing-out access doors on both sides of the engine compartment make it easy to perform important daily service check。

Ecological discharge outlet is easy to maintain,Prevent spillage of potential environmental contaminants。

Centrally located remote pressure tap。

With the help of important information management system(VIMS,Vital Information Management System)Notice of,Operators and service technicians can fix any problems before they occur,This reduces downtime。

● Customer support

It has a long reputation CAT Dealer support

Cat The agent is your right partner.,Ready to meet your needs。

Preventative maintenance program and warranty contract。

First-class parts supply。

Improve your efficiency by training your operators。

Cat Original Remanufactured Parts。

● Sustainability

Sustainability benefits

854K Designed to maximize efficiency and productivity,While protecting natural resources。

The engine idle shutdown feature prevents unnecessary idling,Helps save fuel。

The use of maintenance-free batteries or batteries with extended maintenance cycles reduces the emission of environmental pollutants。

Cat 854K Have multiple life cyclic,One of the most refurbished products。To maximize the service life of the machine,Caterpillar Many sustainability options available,Such as remanufacturing and Certified Rebuild(Certified Renovation)Plan。In these plans,40% savings on reused or remanufactured component% To 70% The cost of,It not only reduces operating costs,,But also help to protect the environment.。

Caterpillar Complete renovation available,Bring new features to old machine,Maximize your resources。When you implement Cat Certified Rebuild When planning,These refurbishment kits are part of the refurbishment process。

● Blade

Reliable blade

Use a blade that is suitable for the bulldozer application,Maximize productivity。

High strength ribbed structure。

Large scale Cat Bolt-on cutting edge and bottom wear plate for track-type tractors。

Optimized width and capacity,Excellent dozing and rolling characteristics。

Coal Shovel

Cat The coal shovel is designed to maintain load control and accommodate large volumes of lighter material,Helps increase productivity。

SU Blade

Will S Shovel and U The characteristics of the shovel are integrated.,Increased capacity,While maintaining the excellent paving characteristics of the straight blade。

Heavy load type SU

For unmatched durability in high-wear applications,SU The blade has the following characteristic:

Hardox 400 Liner and side panels

Additional reinforcement on the bottom of the blade

Product Parameter

ENGINE |

|

Engine model |

Cat® C32 ACERT™ |

Cylinder bore |

145 mm |

Stroke |

162 mm |

Displacement |

32.1 l |

Note(1) |

Nominal net power means the engine is equipped with Power provided at。 |

Note(2) |

Net torque reserve in accordance with |

Note(3) |

Altitude not more than 3050 m(10000 ft) |

Engine |

|

Total power |

676 kW |

Discharge(America EPA Tier |

Total power - SAE J1995 |

Discharge(America EPA Tier |

Net power ISO - 9249 |

Discharge(Tier 2 Equivalent Emission Standard) |

Total power - SAE J1995 |

Discharge(Tier 2 Equivalent Emission Standard) |

Net power ISO - 9249 |

Rated speed |

1750 r/min |

Peak Torque - 1200 rpm |

4242 N·m |

Torque reserve |

30% |

WEIGHTS |

|

Operating weight |

101720 kg |

Gearbox |

|

Type of transmission |

Cat Planetary power shift |

Torque converter drive - First gear forward |

7.1 km/h |

Torque converter drive - Second gear forward |

12.4 km/h |

Torque converter drive - Third gear forward |

21.2 km/h |

Torque converter drive - Reverse first gear |

7.7 km/h |

Torque converter drive - Reverse second gear |

13.5 km/h |

Torque converter drive - Reverse third gear |

23.5 km/h |

Direct drive - First gear forward |

Lockout is disabled |

Direct drive - Second gear forward |

13 km/h |

Direct drive - Third gear forward |

22.8 km/h |

Direct drive - First gear reverse |

8 km/h |

Direct drive - Second gear reverse |

14.3 km/h |

Direct drive - Third gear reverse |

25.1 km/h |

Remark |

Based on 45/65-45 L-5 46 |

Hydraulic system - Promote/Tilt |

|

1850 rpm And 6900 kPa |

610 l/min |

Double acting cylinder - |

177 mm × 1760 mm |

Double acting cylinder - Roll and |

267 mm × 286 mm |

Relief valve setting - |

22675 kPa |

Relief valve setting - |

24560 kPa |

Maintenance refill capacity |

|

Fuel tank - Standard |

1562 l |

Crankcase |

120 l |

Gearbox |

169 l |

Differential - Final drive - Front |

369 l |

Differential - Final drive - Rear |

342 l |

Hydraulic system - Implement and |

326 l |

Hydraulic system - Steering and |

290 l |

SERVICE REFILL CAPACITIES |

|

Cooling system |

200 l |

Axle |

|

Front |

Fixed |

Rear |

With ±10 degree swing |

Maximum lifting distance of single wheel |

573 mm |

Brake |

|

Brake |

Conform ISO 3540:2011 |

Blade |

|

Blade capacity |

25 to 45 m³(33 to 58 yd³) |

Cab |

|

Air conditioner |

Standard Air Conditioning System Package |

Cab - ROPS/FOPS(1) |

With independence ROPS/FOPS Yes |

Cab - ROPS/FOPS(2) |

SAE J1040 MAY94、 ISO 3471:2005 |

ROPS |

ROPS Conform SAE J1040 MAY94、 |

FOPS |

FOPS Conform SAE J231 JAN81 |

Noise performance(1) |

According to ISO 6396:2008 measurement 71 dB(A)。 |

Noise performance(2) |

Standard machine at 15 from it m(49.2 ft) Don't be 87 dB(A)。 |

Noise performance(3) |

Open at operator station and cab |

Noise performance(4) |

According to ANSI/SAE J1166 FEB08 Level 71 dB(A)。 |

Turn |

|

Minimum Turning Radius |

9550 mm |

Total steering angle |

86 ° |

1850 rpm And 6900 kPa Hydraulic output of |

470 l/min |

Relief valve setting |

34500 kPa |

Model 854K(TIER 4) |

|

Serial number prefix |

KK6 |

Model 854K(TIER 2) |

|

Serial number prefix |

RM6 |

Size(Approximation) |

|

Height - ROPS Top |

5590 mm |

Height - Top of the exhaust pipe |

5234 mm |

Height - Top of the hood |

3984 mm |

Ground clearance |

691 mm |

Centerline of front axle to hitch |

2945 mm |

Centerline of rear axle to bumper edge |

4195 mm |

Wheelbase |

5890 mm |

Length - Blade on the ground |

13405 mm |