Global-CE >

Concrete Mixing Plant >

South Highway Machinery Concrete Mixing Plant >

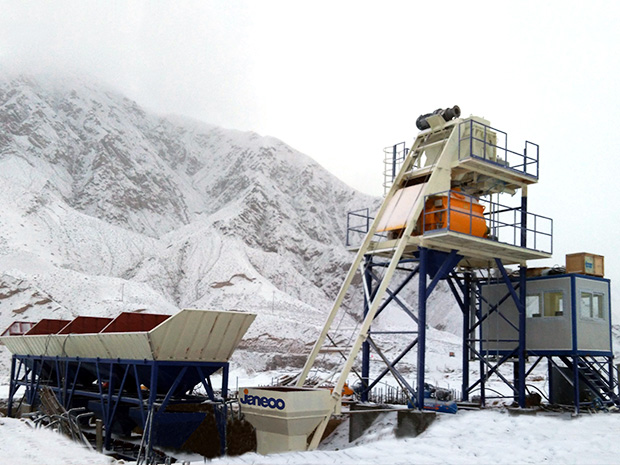

NANFANGLUJI HLS series commercial concrete mixing plant

Product Feature

HLS series commercial concrete mixing plant is composed of mixer material weighing system, material conveying system, material storage system and control system, as well as other auxiliary equipment. Compared with aggregate weighing of concrete mixing plant four intermediate processes are cut. And it is vertically-feed material weighing, saving time and increasing productivity efficiency largely. The efficiency of the plant is 1/3 higher than that of the plant.

The commercial concrete mixing plant developed by NFLG has advantages such as environmental protection, energy-saving, high-efficiency, stability and safety. The types are: HLS120, HLS180, HLS200, HLS225, HLS250 and HLS300.

Product Parameter

| Model | HLS120 | HLS180 | HLS200 | HLS225 | HLS250 | HLS300 |

|---|---|---|---|---|---|---|

| Design production capacity (m3/h) | 100 | 150 | 200 | 225 | 250 | 300 |

| Mixer(twin spiral/twin shaft) | Mixer(twin spiral/twin shaft) | Mixer(twin spiral/twin shaft) | Mixer(twin spiral/twin shaft) | Mixer(twin spiral/twin shaft) | Mixer(twin spiral/twin shaft) | Mixer(twin spiral/twin shaft) |

| Mixer model | JS2000 | JS3000 | JS4500 | JS4500 | JS5000 | JS6000 |

| Power(kW) | 37x2 | 55x2 | 75x2 | 75x2 | 90x2 | 65x4 |

| Output capacity(L) | 2000 | 3000 | 4500 | 4500 | 5000 | 6000 |

| Aggregate size(mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 |

| Aggregate hopper volume | 30x6(Or 45x4) | 30x6(Or 45x4) | 50x6(Or 75x4) | 50x6(Or 75x4) | 50x6(Or 75x4) | 50x6(Or 75x4) |

| Inclined beltconveyor carrying capacity(t/h) | 500 | 600 | 600 | 600 | 600 | 900 |

| Weighing range and accuracy | Weighing range and accuracy | Weighing range and accuracy | Weighing range and accuracy | Weighing range and accuracy | Weighing range and accuracy | Weighing range and accuracy |

| Aggregate scale(kg) | (800-2400)±2% | (1200-3600)±2% | (1600-4800)±2% | (1800-5400)±2% | (2000-6000)±2% | (2400-7200)±2% |

| Sand scale(kg) | (500-1600)±2% | (800-2400)±2% | (1050-3200)±2% | (1200-3600)±2% | 1300-4000)±2% | (1600-4800)±2% |

| Cement scale(kg) | (400-1200)±1% | (600-1800)±1% | (800-2400)±1% | (900-2700)±1% | (1000-3000)±1% | (1200-3600)±1% |

| Fly ash scale(kg) | (130-400)±1% | (200-600)±1% | (250-800)±1% | (300-900)±1% | (300-1000)±1% | (400-1200)±1% |

| Water scale(kg) | (150-500)±1% | (250-800)±1% | (400-1200)±1% | (400-1200)±1% | (400-1200)±1% | (400-1200)±1% |

| Liquid additive scale(kg) | (15-50)±1% | (25-80)±1% | (40-120)±1% | (40-120)±1% | (40-120)±1% | (60-180)±1% |

| Total power consumption(kW)exclude screw conveyor,silo | 155 | 200 | 265 | 265 | 330 | 416 |

| Discharging height(m) | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 |