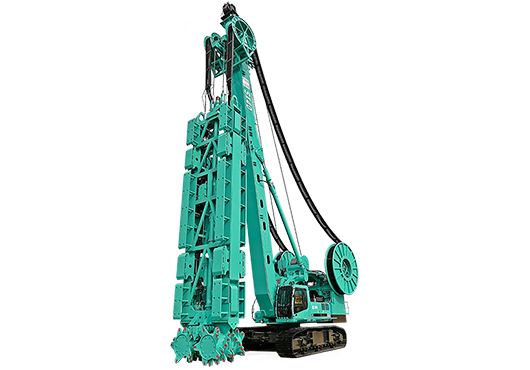

XCMG XTC80 Diaphragm Wall Grab

Product Feature

1.Equipped with XCMG advanced telescopic crawler undercarriage, with features of high strength, high stability and high reliability, well meet trench cutter's working conditions and easy transportation.

2. Eco-friendly, electronically-control, turbocharged, import Cummins Diesel Engine, powerful and high torque output, well matched with reliable hydraulic system, lower fuel consumption and high efficiency.

3. Adopting import double-speed gear box, main winch can accurately control trench cutter's quick up-down motion and low speed feed. Electro-hydraulically proportional follow-up control system can ensure the synchronism of slurry hose drum, hydraulic hose drum and main winch.

4. Front/rear single rope and dual winches, which substantially improves the rope's service life and safety。

5.High output torque of cutter wheels, high working efficiency, and capable of various soil layer and hard rock layer with different cutting teeth. Max. Trench80m.

6. Equipped with advanced inclinometer, longitudinal and lateral adjustment devices, providing high accuracy Omni- adjustment, recording and drawing the wall curve in real time, effectively guaranteeing the wall quality and accuracy.

7. Adopt various advanced control ways, including full power control, electric override control, load sensing control, electro-hydraulically proportional control and others, equipped with import hydraulic parts, realizing high efficiency, high accuracy and high reliability.

8. XCMG have independently developed advanced and reliable electronic control system, integrating engine monitoring system, working condition monitoring system, adjustment system, hose synchronizing system, breakdown inspection and alarm system. Working data can be displayed and saved in real time.Ergonomically design, equipped with full-adjustable seat, air-conditioner, protection device and a large color touchable displayer, easy to operate, being comfortable, safe and reliable.

9. It is equipped with a centralized lubrication system as standard configuration; maintenance is easier.

Product Parameter

| Project | Unit | Parameter |

| Working parameter | ||

| Wall thickness | (mm) | 800~1500 |

| Wall depth | (m) | 80 |

| Main data | ||

| Max. hoisting force | (kN) | 640 |

| Max. hoisting speed | (m/min) | 60 |

| Max. torqe | (kN.m) | 2×80 |

| Rotary speed | (r/min) | 0~25 |

| Slag discharge way | - | Pump |

| Mud pump ability | (m³/h) | 450 |

| Power parameter | ||

| Engine model | - | CUMMINS QSK23 |

| Engine rated power | (kW/r/min) | 567/1800 |

| Undercarrige | ||

| Max. travelling speed | (km/h) | 1.5 |

| Max. grade ability | (%) | 35 |

| Max. clearance | (mm) | 450 |

| Track shoe width | (mm) | 900 |

| Distance between tracks | (mm) | 3700~5100 |

| Working condition | ||

| Total lengh | (mm) | 10960 |

| Total width | (mm) | 5100 |

| Total height | (mm) | 17500 |

| Working radius | (mm) | 4500~5100 |

| Transportation condition | ||

| Total lengh | (mm) | 14175 |

| Total width | (mm) | 3700 |

| Total height | (mm) | 3460 |

| System parameter | ||

| Max.system pressure | (MPa) | 32 |

| Max. system flow | (L/min) | 2×285+352 |

| Weight parameter | ||

| Bare weight | (t) | 100 |

| Frame weight | (t) | 30~36 |