Product Feature

Features

Metso maintains the original engineering drawings, quality standards, and process design for all Holo-Flites® manufactured over the past sixty years.

- Western Precipitation Holo-Flite®

- Joy Manufacturing Holo-Flite®

- Denver Holo-Flite®

- Denver-Sala Holo-Flite®

- Denver-Svedala Holo-Flite®

- Svedala Holo-Flite®

Holo-Flite® Features

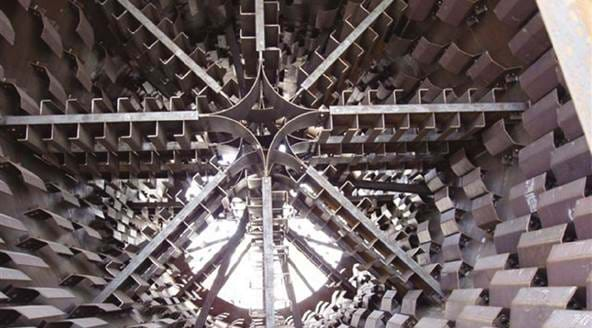

- Particles are indirectly heated or cooled via the hollow flights, shaft, and trough

- Heat transfer is achieved by using water, steam, or thermal oil

- Heat transfer process can be easily controlled to achieve the best results

- Extreme expansion and contraction of the screw is easily handled by the Holo-Flites patented twin pad design that allows for successful operation up to 1,200 degree Celsius for product cooling

Product system offering/ ancillary equipment offering

- Standalone unit for heating, drying, cooler

- Thermal fluid heating system

- Wet scrubbing for off gas handling system

- Dust collection for off gas handling system

- Cooler water heat exchanger

- Feed and takeaway systems

- Rotary Air Locks

- PLC/ HMI controls

- Structural Steel

- Commissioning & Process Audit services

Benefits

- Low power consumption

- Mechanical simplicity

- Continuous operation

- Low maintenance

- No operator required

Product Parameter

| Standard range of sizes and capacities for Holo-Flites | |

|---|---|

| Screw diameter | 7 inches to 36 inches |

| Length | 12 ft to 28 ft long |

| Throughput range | up to 50T/hr per unit |

| Heating | heats material up to 500°F |

| Material moisture | reduces a wide range of feed moisture content |

| Cooling | accepts 1900°F |